We have chain weaving & welding equipment 20 sets, first step and second step calibration equipment 6 sets,heat treatment 4 sets, proof test machine 3 sets,vertical tension machine 2 sets.Our chain working temperature is -40℃-200℃,each piece has it’s “ID CODE MARK”,from it we can check the source goods.

Where is our chain’s advantage?

- we get calibration for each 5-7 links of chain, we do first time calibration, then heat treatment, and second calibration, after the second time calibration we do 2.5 times 6 meter proof pull test,we can make sure the chain pinch resilience. heat treatment with double frequency conversion, constant temperature control.

- Hardness testing,chain of EN818-7 for chain block ,require the straight arm HR38(37-40) , R angle HR42, elongation less than 15%;chain of EN818-2 for chain slings ,require elongation 15%-20%,R angle is for high friction,long using life, straight arm confirm the elongation.

- Chain black treatment, we don’t take normal way of weakly acidic liquid, we take military technology, the black layer with high thickness,and no down the tensile.

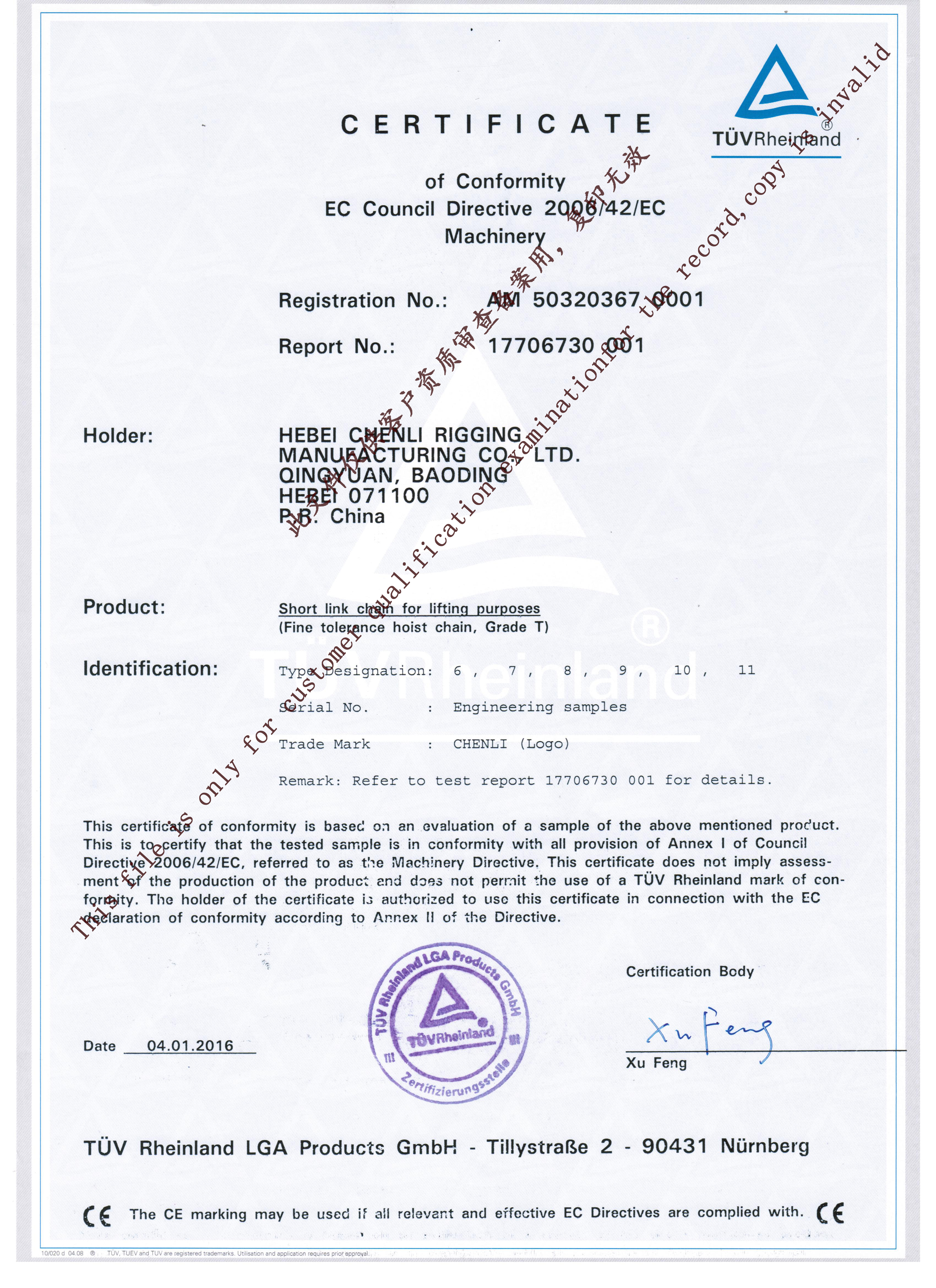

- Each size of chain quality stability meets or exceeds the GB, EN,ISO,DIN standard.By our company large qty sample continuous testing, Chenli chain’s breaking load, elongation,chain surface hardness test and consistency level lead the industry, even exceed GB, International standard. Factory chain the batch pass rate is 100%.

Post time: Oct-08-2021